Introduction

We needed a frame clamp that we could use when doing frames on solid pieces. This is our

solution and we will be refining the design as we go.

All the measurements are for the one we built, for example we used a 20mm thick piece of

Aluminium only because we had it in a drawer this could be made using 25mm square stock

it could also be made using wood and a t nut but would need scaling up to allow for the flex

in the wood

If you are converting this to imperial measurements please substitute the drill, bolt, nut and

tap sizes accordingly.

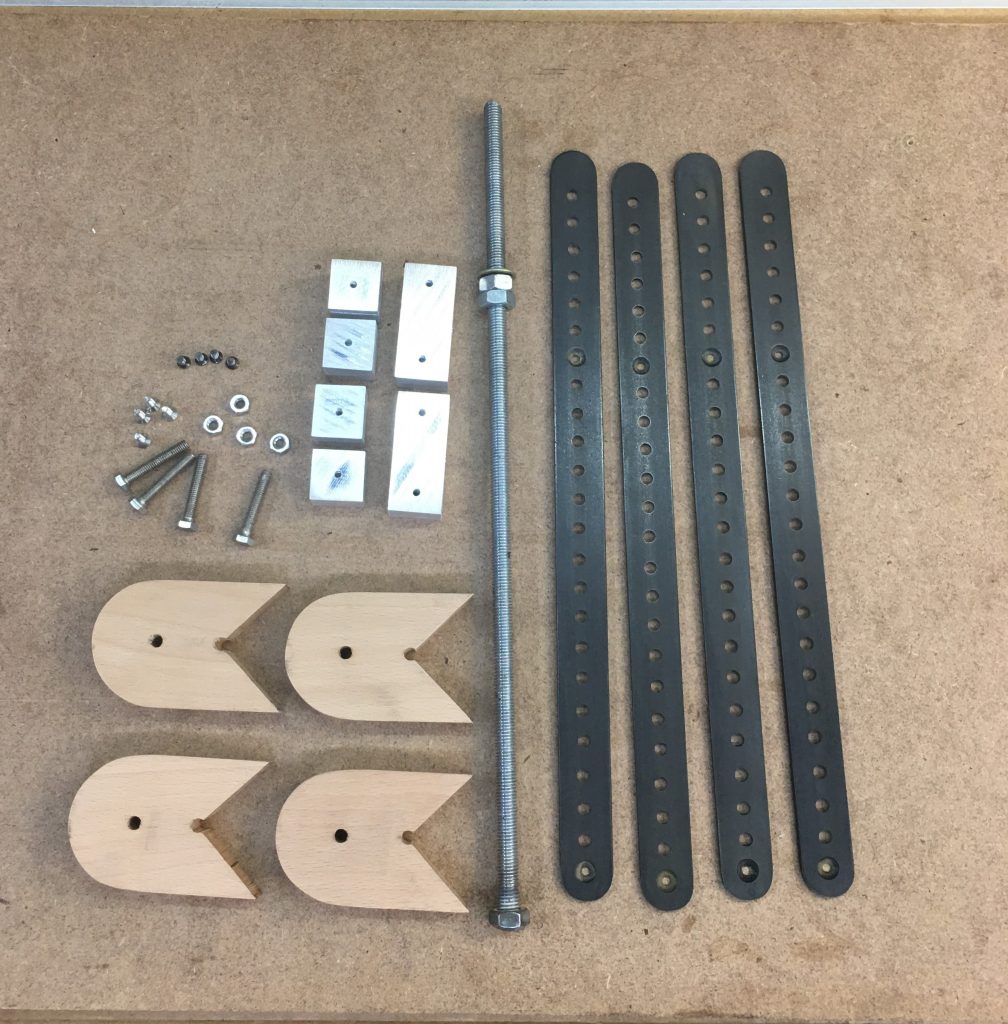

Material List

● 4 Lengths of 4mm thick Steel 25mm wide 360mm long

● 4 pieces of hardwood or Ply 80mm x 60mm x 20mm

● 4 pieces of aluminium 25mm x 25mm x 20mm

● 2 pieces of aluminium 60mm x 25mm x 20mm

● 8 M5 countersink bolts 10mm long

● 4 M6 Bolts 30mm long

● 4 M6 nuts

● 4 Penny Washers

● 1 length M10 Threaded rod 400mm long

● 3 or 4 M10 Nuts

● 1 M10 Washer

Essential Tools to make this Version.

1 x Tap and die set

Method.

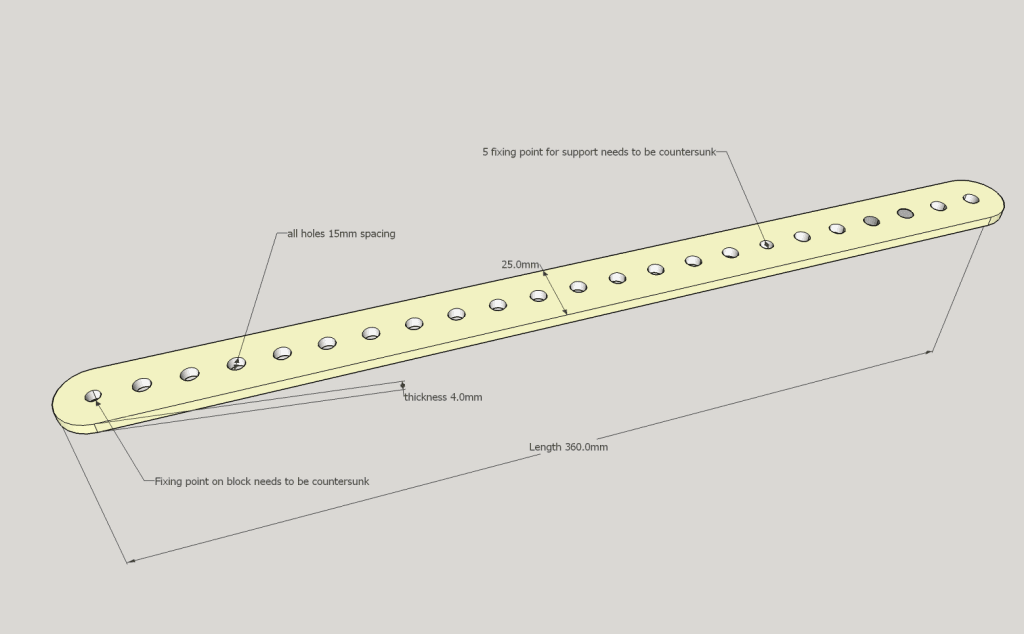

Steel Arms

Cut the steel to your desired length in our case 360mm,

Mark a line down the centre of the steel and mark for the holes at 15mm spacing

Drill the two holes indicated on drawing 1 5mm diameter and countersink

Drill the remaining holes 6 mm diameter

Round the ends of the arms if you wish

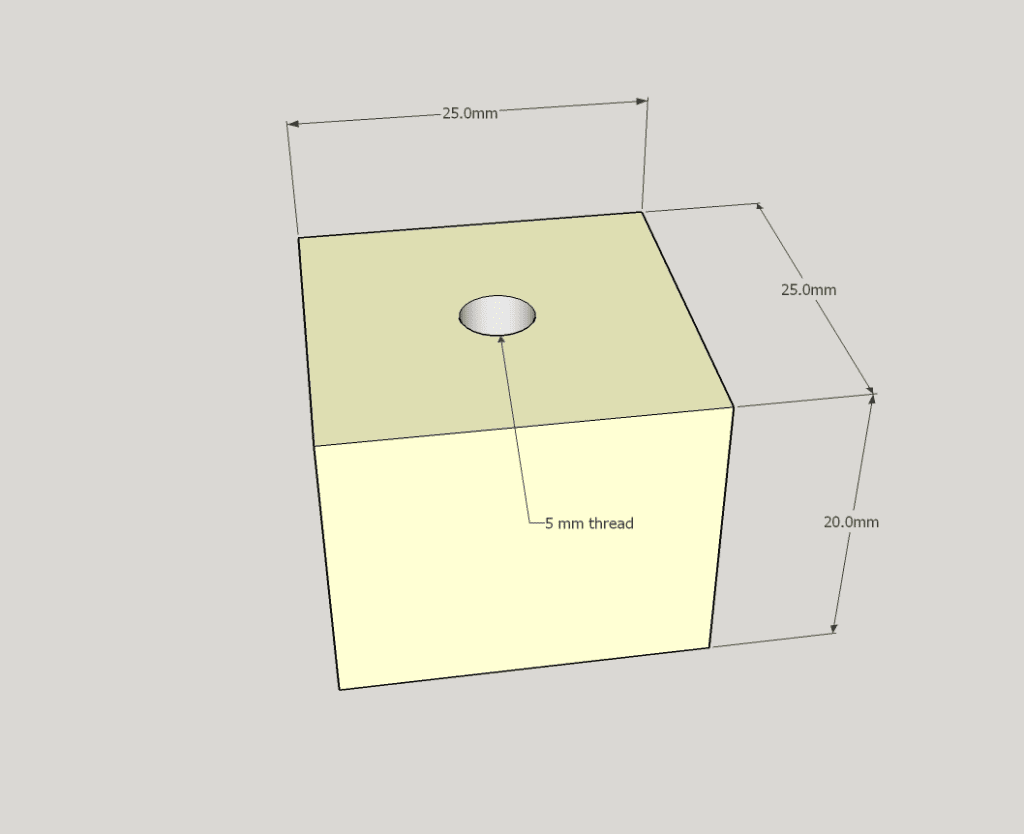

Support blocks

The support blocks are simple to make in our case they are 25mm x 25mm x 20 mm

Find and mark the centre and drill a 3.3 mm hole then thread the holeusing a M5 tap

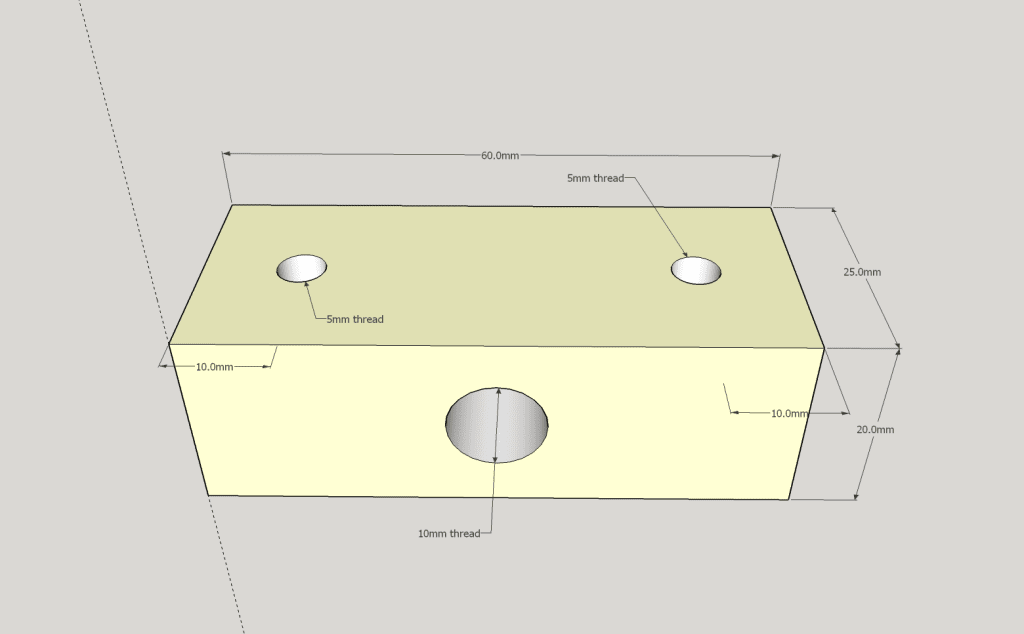

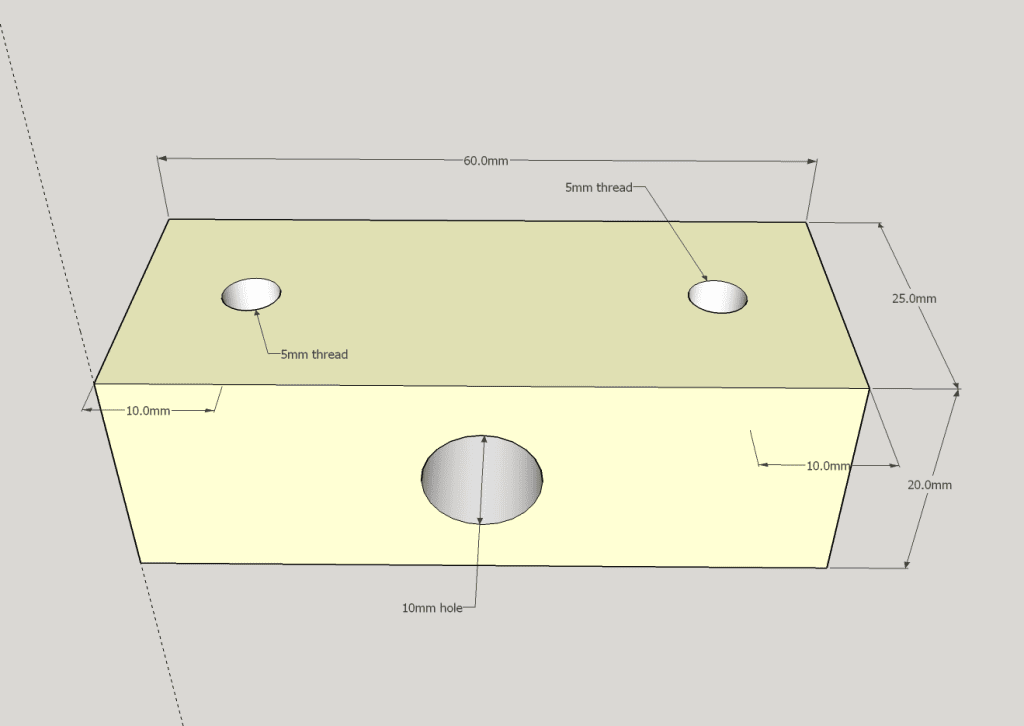

Clamping blocks

The two blocks are 60mm x 25mm x 20mm

First mark a centre line lengthways on the top and front face

On the top face measure in 10mm from each end and mark on the centre line

Drill the two marks 3.3 mm and then thread the hole using a M5 Tap

On the front face measure 30mm from the end and mark it

On one clamp Drill the mark 8.5 mm and thread the hole using a M10 x 1.5 tap

On the second clamp drill out the hole to 10mm.

Threaded rod

Cut a length of 10mm threaded rod to 400mm long

On our version we welded a nut on one end of the rod, but you could just use two nuts and

tighten them together.

The remaining two nuts can be wound down the thread to any point you desire place the

washer on the rod last before assembly.

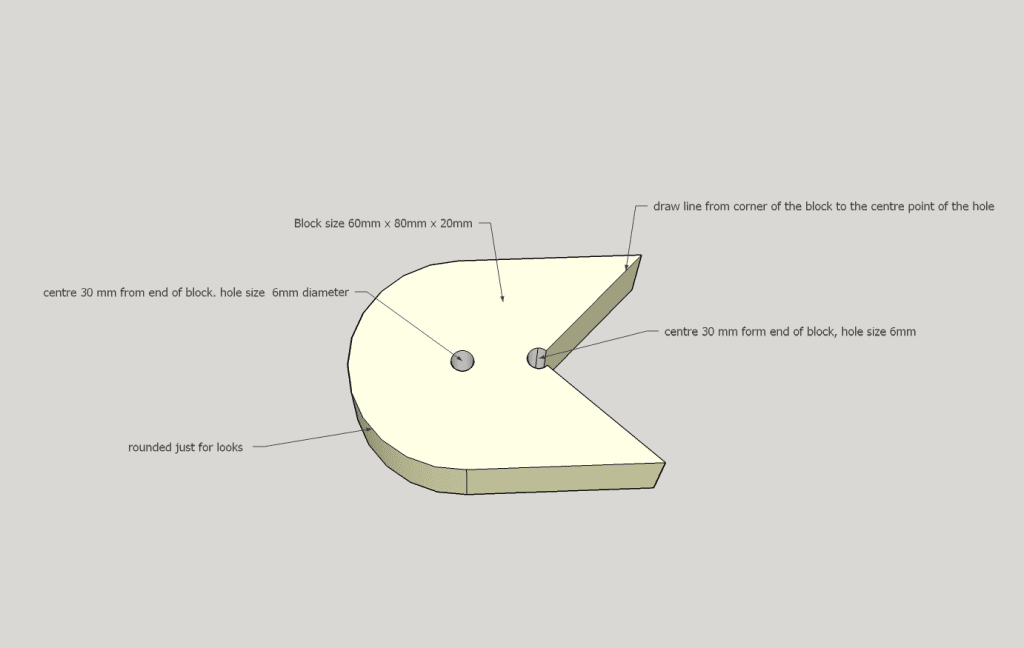

Jaws

The jaws were made from 20mm thick beech but can be made from any hardwood, plywood

or even solid plastic

They measure 60mm x 80mm x 20mm

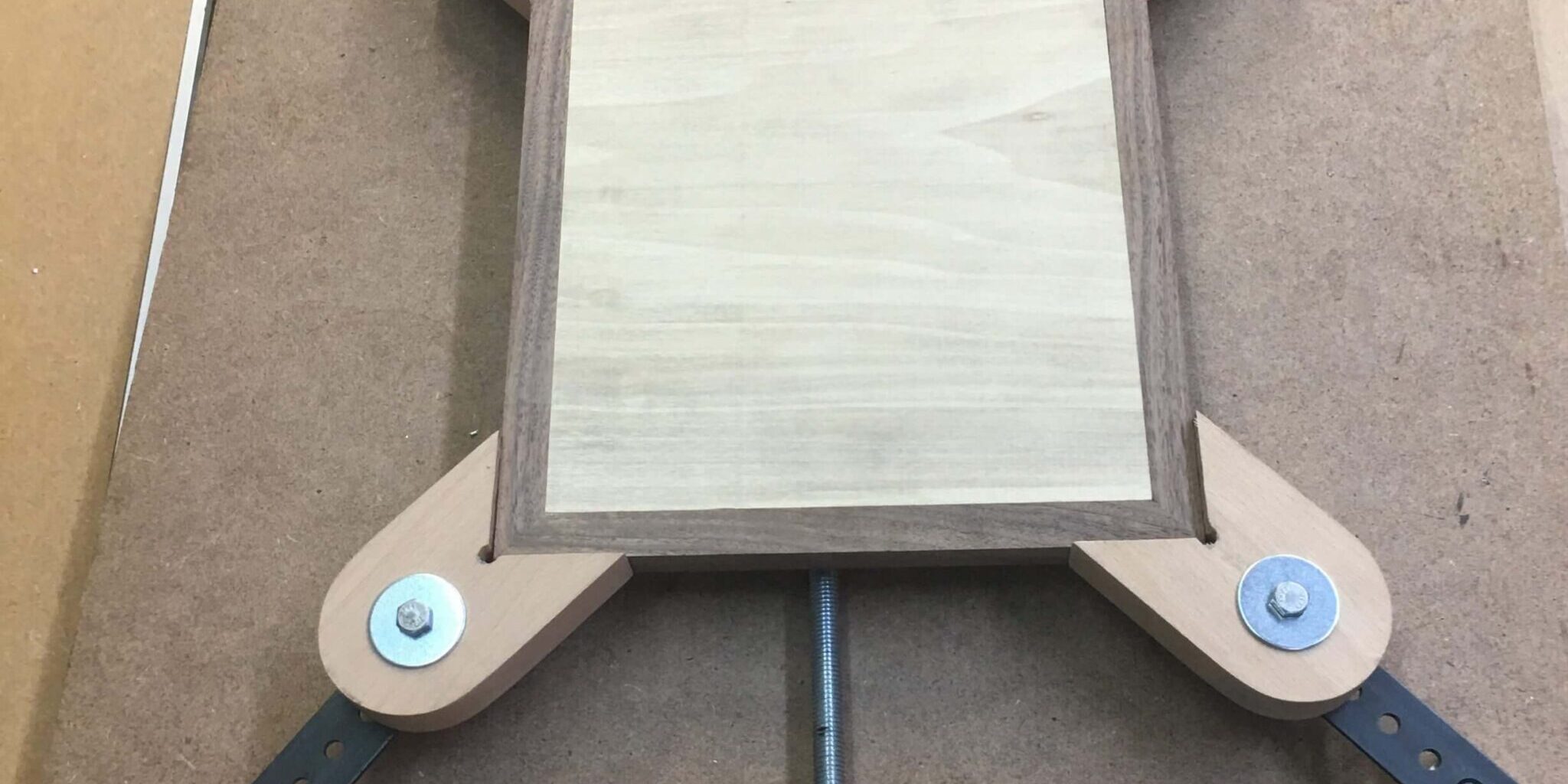

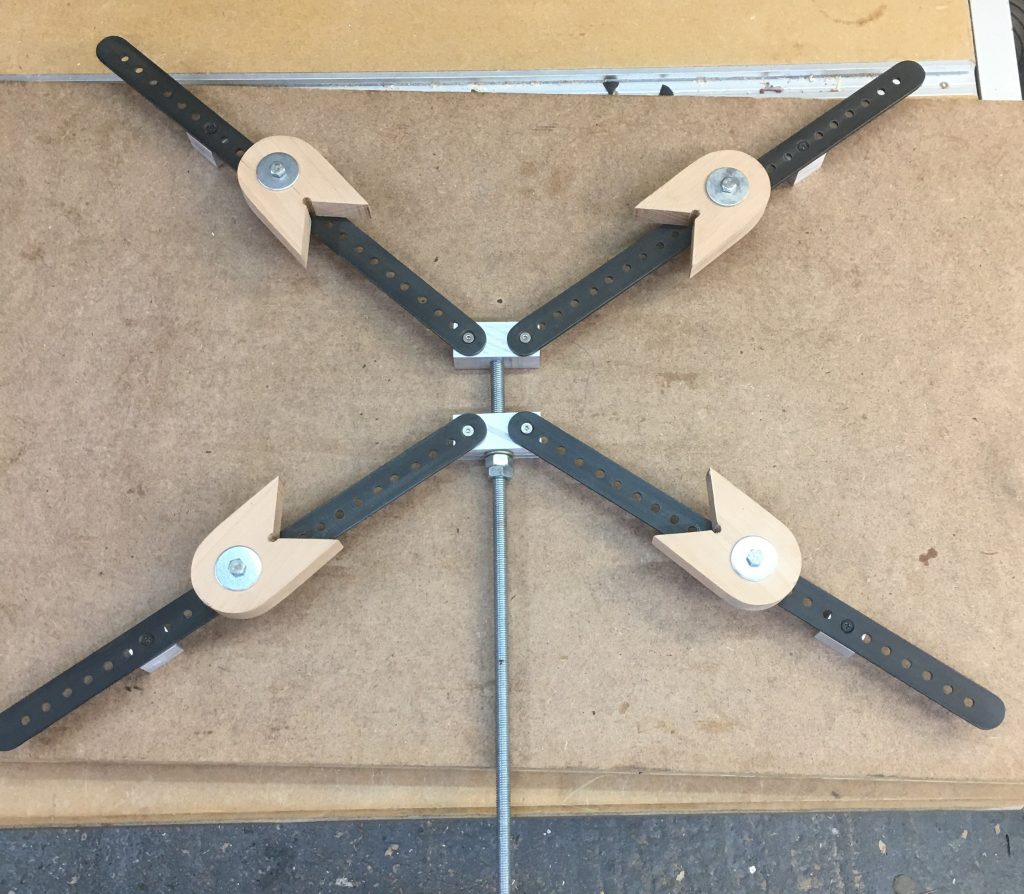

Assembly.

To assemble the jig, push the clamp that has the 10mm hole in it over the threaded rod and

screw the rod into the second clamp.

Screw the arm supports to the steel bar using the M5 Countersink bolts

Screw the arms to the clamps again using the M5 Countersink Bolts

Lastly attach the jaws to the arms using the M6 bolts , penny washers and nuts

Do not over tighten the jaws as they need to swivel a little when clamping